A “Transformação Sustentável” determina nossa atividade econômica futura

A indústria, como um todo, tem a responsabilidade de reduzir seus impactos ambientais. As exigências legais e a crescente pressão social desencadearam um processo de repensar: líderes agora veem a necessidade de reavaliar o impacto ambiental de seu trabalho.

Para muitas empresas, a viabilidade econômica das medidas ecossustentáveis ainda é um grande desafio. No entanto, elas também reconhecem a oportunidade de melhorar sua própria competitividade em termos de produtividade, custos e qualidade por meio da transformação sustentável.

NOSSA EXPERTISE? GO GREEN.

Como a melhor consultoria de Lean Management da Alemanha, sabemos como otimizar processos, prevenir desperdícios e mudar sistemas de criação de valor de forma holística e sustentável. Analisamos os processos de criação de valor existentes, identificamos o potencial de sustentabilidade e trabalhamos com você para implementar soluções baseadas nas necessidades para suas metas de CO₂.

ESTRATÉGIA E ROADMAP

Para seguir um alvo claro desde o início, é importante ter uma visão geral da gestão de sustentabilidade existente. Quais processos, estruturas e responsabilidades são usados para ancorar o tema na organização? Que campos de ação já foram definidos? Apoiamos você na definição da sua estratégia de sustentabilidade e na seleção e revisão de medidas eficazes.

As cadeias de suprimentos estão se transformando cada vez mais em cadeias de valor multidimensionais, complexas e globais. O domínio das cadeias de valor sustentáveis está, portanto, se tornando um dos maiores desafios para o desempenho da sustentabilidade nas empresas. A abordagem de cadeia de suprimentos sustentável da Staufen apoia as empresas desde a estratégia até a implementação e ajuda a alinhar de forma sustentável toda a rede com os requisitos futuros e a controlá-la com confiança por meio de sistemas de gestão transparentes.

Preventing waste in operational processes is part of our core business and offers great potential for the reduction of raw materials and energy. We support you in expanding a resource-optimized value creation system and ensure best-of-class results in your production.

Sustainable companies need new leadership methods and competencies.

After all, managers who act sustainably today not only have an economic responsibility, but also a social and ecological one. They act as role models and should enable their employees to think and act sustainably. A company has a sustainable corporate culture only if there is a shared understanding among a sustainably acting organization at all levels.

Our change management approach enables companies to establish leadership methods, organizational structures and systemic processes that make them more sustainable and thus more fit for the future.

Process mining involves mining the data streams of corporate networks. The aim is to leverage unused potential or prevent waste. This method can also be used to achieve greater transparency in the area of sustainability. With the help of the Execution Management System (EMS) from our digital partner Celonis, we can screen companies, identify problems and quickly derive recommendations for action thanks to AI.

In contrast to classic transaction systems, Celonis links the processes and offers a complete view, from raw materials to logistics, and production to delivery.

Depending on the case, more than just the classic economic factors are examined. Sustainability factors can also be filtered out: risk mapping, emissions, social standards, etc. Once all the data has been compiled, the sustainability of the entire value chain can be determined.

HOW DO YOU BECOME A CO₂-NEUTRAL COMPANY?

General energy savings and a CO₂-neutral energy supply are currently the most important ecological goals for many companies. This is not just about in-house production; emissions from the upstream supply chain must also be taken into account.

Corporate Carbon Footprint

What emissions does an organization produce in a given period of time (end-to-end process)?

Product Carbon Footprint

What emissions does a product cause in product lifecycle/value chain “cradle-to-grave” or “cradle-to-ramp”?

Project Carbon Footprint

What emissions does a particular project produce for a particular period of time?

HOW IS THE CO₂ FOOTPRINT MEASURED?

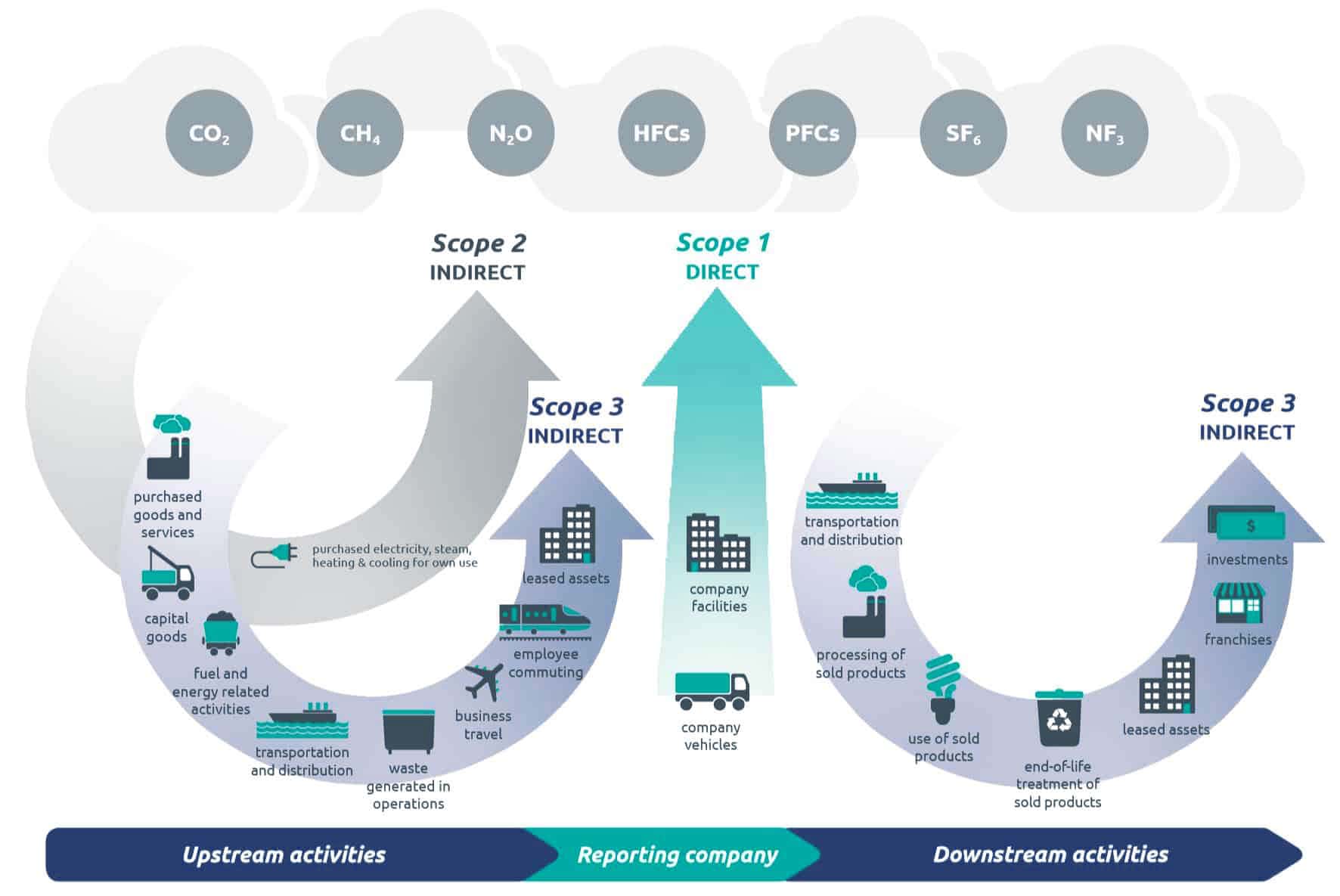

The CO₂ footprint can be measured along the value chain according to its contribution to the emission of CO₂ equivalents.

Direct emissions within the company’s operations and internal power generation

Indirect emissions from external electricity generation for Group operations

All indirect emissions caused by the company; includes emissions within the supply chain of products and services, employee travel and commuting, and the entire life cycle of products

THE LEVERS FOR PREVENTING CO₂ EMISSIONS

Avoidance

- Global Footprint: readjusting the supply chain network

- Manufacturing Footprint: improving manufacturing processes

- Product Lifecycle: optimized product development, end-to-end

Reduce

- Energy efficiency in buildings: Green Building

- Energy efficiency in buildings: energy management

- Sourcing alternative energies, green electricity and off-grid

Compensate

- Compensation of unavoidable emissions: emissions trading, CO₂ certificates

- Corporate carbon management financing of climate protection projects

THE GREEN TRANSFORMATION CAN MAKE COMPANIES MORE EFFICIENT AND COMPETITIVE

Our team looks forward to answering your questions and supporting you on your successful path to becoming a CO₂-neutral company.